PTUK Course (1): Solar Energy Systems (renewable energy)

Completion requirements

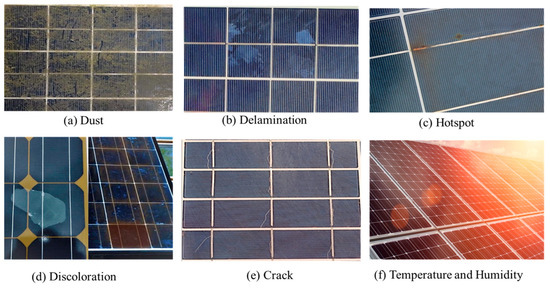

Common defects in photovoltaic (PV)

Common defects in photovoltaic (PV) cells can significantly reduce their efficiency and overall performance. These defects can arise from various stages of the PV cell manufacturing process, including material preparation, cell construction, and module assembly. Here are some common defects and their causes:

1. Crystalline Defects

- Description: These defects occur within the crystal structure of the semiconductor material, such as silicon.

- Causes:

- Material Impurities: Contaminants in the raw material or during the crystal growth process can lead to the formation of defects.

- Poor Crystal Growth: Inadequate control of temperature and environmental conditions during the crystal growth process (e.g., Czochralski process) can result in dislocations, grain boundaries, or inclusions within the crystal.

- Mechanical Stress: Handling or processing the wafers under mechanical stress can introduce micro-cracks and dislocations.

2. Surface Defects

- Description: These defects are imperfections on the surface of the PV cell that can impede light absorption or cause recombination of charge carriers.

- Causes:

- Improper Surface Texturing: Inconsistent or poor surface texturing can lead to uneven surfaces, reducing light absorption efficiency.

- Contaminants: Dust, dirt, or residues from the manufacturing process left on the surface can block sunlight or introduce electronic states that increase recombination.

- Scratches and Micro-cracks: Handling and processing errors during manufacturing, such as cutting and polishing, can cause scratches or micro-cracks on the surface.

3. P-N Junction Defects

- Description: Defects in the p-n junction, the critical interface between the p-type and n-type materials, can reduce the cell’s ability to separate and collect charge carriers.

- Causes:

- Non-Uniform Doping: Inconsistent or incorrect doping during the manufacturing process can create areas where the p-n junction is not properly formed, leading to poor charge separation.

- Junction Leakage: Imperfections at the p-n junction can cause leakage currents, where charge carriers recombine rather than contribute to the electric current, reducing efficiency.

- Edge Effects: Poor control of the junction formation at the cell edges can lead to defects that increase recombination and leakage.

4. Shunt and Series Resistance

- Description: Shunt and series resistances are types of electrical defects that can cause significant power losses in PV cells.

- Causes:

- Shunt Resistance: Low shunt resistance is often caused by manufacturing defects, such as cracks or pinholes, which create unintended current pathways. It can also result from poor edge isolation or contamination.

- Series Resistance: High series resistance can result from inadequate contact between the metal electrodes and the semiconductor, poor quality of the metal grid, or excessive distances that electrons must travel through the material, leading to higher energy losses.

5. Metallization Defects

- Description: These defects involve issues with the metal contacts (electrodes) that collect and transport the electrical current generated by the PV cell.

- Causes:

- Poor Contact Adhesion: If the metal contacts are not properly adhered to the semiconductor surface, they may lift or separate, reducing the efficiency of current collection.

- Grid Line Defects: Inconsistencies in the thickness or width of the front metal grid lines can lead to increased resistance or shading, reducing the cell’s performance.

- Soldering Issues: Poor soldering during module assembly can cause weak connections that lead to increased resistance or open circuits.

6. Encapsulation Defects

- Description: These defects occur during the encapsulation process, where the PV cells are protected with layers of material to shield them from environmental factors.

- Causes:

- Delamination: Separation of the encapsulation layers due to poor bonding or thermal cycling can expose the cells to moisture and oxygen, leading to degradation.

- Bubbles and Voids: Trapped air or gas during the encapsulation process can form bubbles or voids, which can increase the risk of moisture ingress and reduce light transmission.

- Yellowing: Over time, some encapsulant materials may degrade and yellow, reducing the amount of light reaching the cells and decreasing efficiency.

7. Thermal Defects

- Description: These defects are related to the thermal behavior of the PV cell and can impact its long-term reliability.

- Causes:

- Hot Spots: Hot spots can develop due to localized defects, such as cracked cells or poor electrical connections, leading to uneven heating, which accelerates degradation.

- Thermal Expansion Mismatch: Differences in the thermal expansion coefficients of the materials used in the cell can lead to mechanical stress, causing micro-cracks or delamination over time.

8. Light-Induced Degradation (LID)

- Description: LID refers to the reduction in efficiency that occurs when PV cells are first exposed to sunlight.

- Causes:

- Boron-Oxygen Complex Formation: In silicon-based cells, exposure to light can cause boron and oxygen atoms to form complexes that reduce the cell’s efficiency.

- Material Defects: Defects within the silicon material, such as impurities or dislocations, can become more active under light exposure, leading to increased recombination losses.